The Ultimate Guide to Quantity Take-Off for Construction Professionals

In a dynamic construction environment, accuracy isn’t a luxury—it’s a necessity. Quantity Take-Off (QTO) is one of the most vital steps in ensuring the project’s feasibility, budget control and successful delivery. Whether you’re working on the small-scale residential builds or any of the large infrastructure projects, mastering the Quantity Take-Offs helps you to drive efficiency, reduce the waste and even gain a competitive edge.

This comprehensive guide explores what Quantity Take-Off is, why it matters, how to do it effectively and how innovations like BIM Services and 5D integration are transforming this landscape.

Â

What Is Quantity Take-Off and Why Does It Matter?

Quantity Take-Off is the process of accurately determining the quantities of materials, labour and equipment needed for a construction project. These quantities are usually derived from the project drawings, specifications or even the 3D models.

Why it’s crucial:

- Establishes a clear baseline for cost estimations

- Ensures the efficient procurement of materials

- Aids in the scheduling and resource planning

- Minimizes the risks and enhances the project profitability

Â

Why Quantity Take-Off is the Backbone of Construction Cost Control?

Construction success hinges on the effective cost management and Quantity Take-Off is the foundation of any reliable estimate. A small miscalculation in quantities can snowball into budget overruns, delays and even the supply issues.

Â

Key Benefits of Accurate Quantity Take-Off:

- Competitive, yet profitable bidding

- Avoidance of the material shortages or surplus

- Streamlined planning and execution

- Improved collaboration among the stakeholders

Â

How to Perform Quantity Take-Off: A Step-by-Step Process

Mastering Quantity Take-Off involves a mix of the technical expertise, logical planning and careful documentation. Here’s a simplified process:

1) Review Project Documentation

Start by reviewing all the project documentation—architectural, structural and MEP drawings. Resolve any of the discrepancies before beginning the measurements.

2) Segment the Scope

Break the project into the components such as site prep, structure and finishes for better manageability and tracking.

3) Select Appropriate Units of Measurement

Stick to standard formats such as cubic meters for concrete or square feet for flooring to avoid confusion.

4) Perform Accurate Measurements

Use either the manual scaling for the 2D drawings or model-based measurements if using the BIM.

5) Factor in Wastage and Contingencies

Include the realistic allowances for any of the breakage, cutting loss or even for the project-specific variables.

6) Document Everything

Record all the assumptions, exclusions and notes for future reference or clarification.

7) Verify and Review

Double-check all the quantities, especially in the complex areas. Use peer reviews to validate the results.

Â

Modern Tools and Techniques That Streamline Quantity Take-Off

Digital transformation has enhanced how we approach the take-offs. Today’s estimators have powerful tools at their disposal to streamline the tasks and minimize the human errors.

Must-Have Software:

- Bluebeam Revu – For 2D PDF take-offs

- Planswift – Drag-and-drop Quantity Take-Offs for 2D drawings

- CostX – Combines Quantity Take-Offs with estimating capabilities

- Autodesk Revit + Navisworks – For model-based Quantity Take-Offs as part of BIM Services

Â

The rise of 5D BIM Services allows seamless integration of the cost data with time and model elements, offering a dynamic and real-time approach to estimation.

Â

Best Practices:

- Use color codes to visually track completed take-offs

- Automate the repetitive tasks and templates for common scopes

- Integrate the take-offs into scheduling and procurement workflows

Â

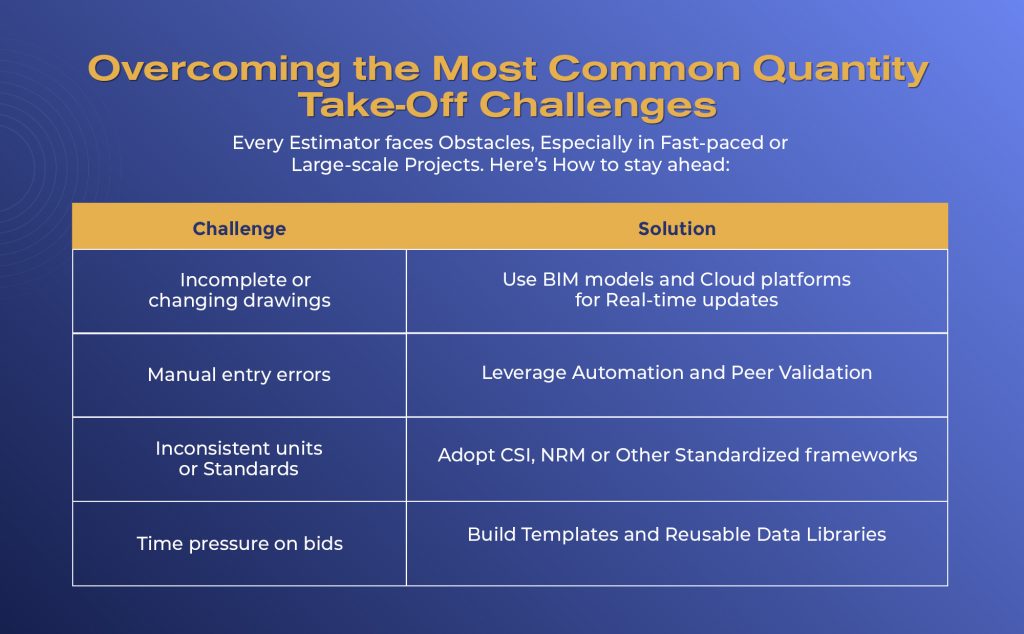

Overcoming the Most Common Quantity Take-Off Challenges

Â

Real-World Wins: Case Studies

Melbourne High-Rise Project

A switch from manual Quantity Take-Off to BIM-based workflows cut estimation time by 35% and eliminated overordering errors worth $100,000.

UK Healthcare Facility

Quantity Take-Off integration with the MEP design flagged inconsistencies early, avoiding the costly onsite reworks and ensuring the schedule adherence.

US Industrial Plant

Cloud-based Quantity Take-Off tools enabled the real-time collaboration across multiple states, streamlining the procurement and execution.

Â

Expert Tips to Elevate Your Quantity Take-Off Game

- Stay updated with the latest software trends – Learn tools that sync well with the BIM platforms.

- Create standardized templates – This reduces time spent on the repetitive tasks.

- Collaborate closely with the field teams – Get practical insights on the material usage.

- Use past data as benchmarks – Do reference the actual project metrics for better forecasting.

- Document your process thoroughly – Clear assumptions leads to the clearer decisions.

Â

Â

Conclusion: Why Quantity Take-Off Mastery Is a Game-Changer

Accurate quantity take-offs are essential for controlling the costs ensuring the timely procurement and winning the profitable bids. By embracing the digital tools, applying proven strategies and even incorporating the innovations like 5D BIM Services, the construction professionals can dramatically improve both speed as well as the accuracy.

Ready to elevate your estimation skills?

At QeBIM, we specialize in delivering accurate and timely Quantity Take-Off services using the latest digital tools along with the BIM methodologies. Whether you’re bidding on a project or managing the large-scale execution, we help you to build smarter, estimate better and deliver with confidence.

Contact us today to learn how we can help out in your next project!