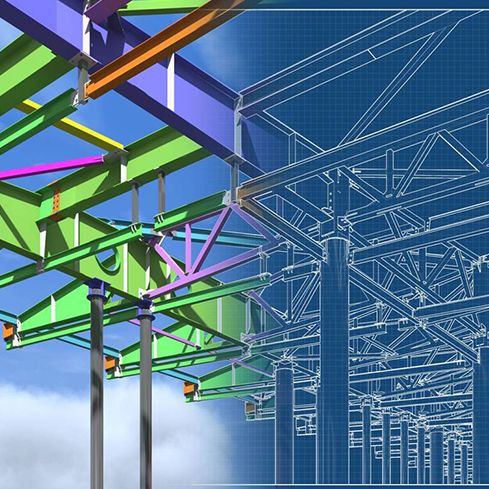

Build with confidence from design to fabrication

At QeBIM, we turn structural design intent into accurate, fabrication-ready deliverables through our expert Fabrication Drawing Services. Every beam, column, connection, weld, and assembly is detailed exactly as it will be built, reducing rework, avoiding clashes, and accelerating production timelines. With advanced BIM and CAD workflows, we provide fully coordinated drawings that support contractors, fabricators, engineers, and erection teams. Our Steel Shop Drawing Services enhance constructability, improve site safety, and ensure seamless progress from design to erection.

Our fabrication drawing services ensures

- • 98.6% first-pass approval rate with fabricators and QA teams

- • 50% average reduction in RFIs during erection when using our shop drawings

- • Flawless project deliveries across commercial, industrial and infrastructural sectors

Our team of experts have delivered around 1,200+ steel fabrication packages ensuring the quality and following the required building codes for hassle-free fabrication on-site.

25+ Years

12500+

25+

1500+

Detailed Spread of Our Shop Drawings Solutions

Structural shop drawing services

Steel fabrication drawing services

Steel shop drawings services (assembly & erection)

Connection design & detailing

Plate nesting & cutting files

Shop BOMs & material schedules

Millwork & secondary element coordination

Revision control & as-built updates

Model to manufacture — we speak the machine language

Trusted engineering-to-fabrication workflow

We combine structural expertise with fabrication experience so drawings are not only technically correct but shop-friendly.

Single-source coordination

BIM-driven clash checks, coordinated MEP penetrations and embedded items to avoid on-site surprises.

Fast, reliable delivery

ISO-style QA checkpoints, version control and deterministic delivery milestones for tight fabrication schedules.

Fabricator-first outputs

We produce CNC-ready files, nesting sheets and clear match-marking to speed shop workflows.

Global experience, local compliance

Projects across regions with familiarity in international steel standards and local codes.

Advantages of Steel Shop Drawings

- Reduce fabrication errors — Clear tolerances, fit checks and connection details reduce rework.

- Faster shop throughput — CNC files and optimized nesting accelerate cutting and assembly.

- Safer erection — Erection sequences, lift plans and temporary bracing minimizes the site risks.

- Cost clarity — Accurate BOMs and weight summaries enables better procurement and logistics planning.

- Traceability & QA — Revision logs and material callouts supports inspection and compliance.

We model, detail and export for manufacture using top notch tools

We deliver solution for Industrial, commercial & infrastructure steelwork

Have any questions? here some answers?