How BIM Modeling Simplifies Complex MEP System Design?

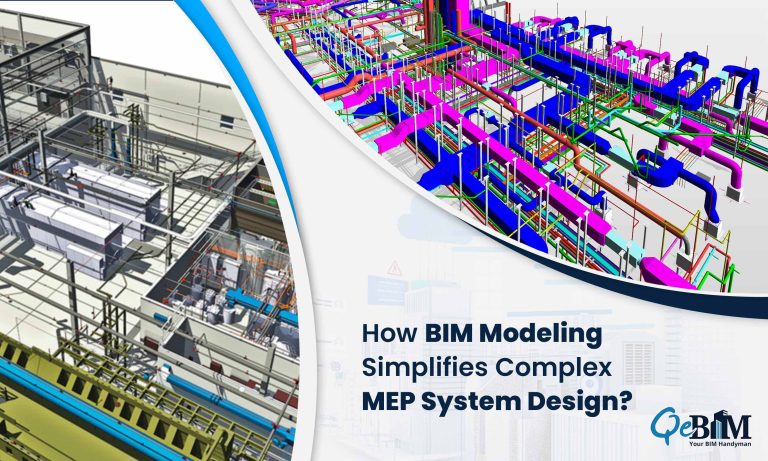

In today’s construction scenario, the mechanical, electrical and plumbing (MEP) systems are growing increasingly critical. From high-rise buildings to smart hospitals and data centers, these intricate systems requires precise design coordination to ensure safety, efficiency and sustainability. This is where BIM Modeling for Complex MEP Systems becomes a game-changer.

By leveraging the BIM Services the project teams can visualize, coordinate and manage even the most complex MEP designs with accuracy thereby reducing the reworks, delays and cost overruns.

Let’s dive into the key challenges in MEP modeling and explore how the MEP BIM Services provide practical solutions.

Why MEP Systems Are Complex?

Modern MEP systems are interdependent, spanning HVAC ducting, fire protection, electrical conduits, water supply, drainage and more. In large-scale or specialized facilities like hospitals, airports and industrial plants—these systems often overlap within the limited ceiling spaces, making design and coordination a major challenge.

A report by McKinsey Global Institute reveals that nearly 30% of construction rework is caused by the design coordination issues, much of which involves the MEP systems. Traditional 2D drafting can’t efficiently handle such complexity, often leading to clashes during the construction.

Key Challenges in BIM Modeling for MEP Systems

1) High Level of Design Interdependency

Each MEP component impacts others—altering the duct routes might interfere with the electrical conduits or plumbing lines. Managing these interdependencies without an integrated system leads to the design conflicts and inefficiencies.

2) Space Constraints

In the dense architectural spaces, fitting multiple services without compromising the performance is tough. Especially in retrofits or renovations, aligning the new MEP layouts with existing structural conditions becomes a technical puzzle.

3) Coordination with Structural and Architectural Models

One of the major challenges is ensuring seamless coordination between MEP systems and the architectural and structural components. Without a centralized BIM environment, multidisciplinary teams often face misalignments that results in costly on-site changes.

4) Data Accuracy and Version Control

In large projects involving multiple consultants, maintaining up-to-date and consistent models is a challenge. Any uncoordinated update can propagate errors across teams thereby leading to the conflicts during the construction.

5) Managing Large File Sizes

High-detail MEP models can become computationally heavy especially when the LOD (Level of Detail) exceeds 300 or 400. Handling such data-rich models requires the robust coordination workflows and hardware capabilities.

Solutions Enabled by MEP BIM Services

1) Clash Detection and Coordination

BIM-based clash detection tools like Navisworks and Revit automate the identification of conflicts between the MEP, architectural and structural models. This early detection can reduce reworks by up to 50%, according to Autodesk industry insights.

2) Parametric Modeling for Precision

Parametric modeling ensures that every MEP element is connected with the real-world data—equipment size, material type and performance specifications. This enhances the coordination accuracy across the design and construction phases.

3) Spatial Optimization and Routing

BIM allows the designers to simulate service routes in 3D thus ensuring the optimal use of space while maintaining the accessibility for maintenance. This is particularly useful in hospitals, data centers and cleanroom facilities where the system reliability is paramount.

4) Enhanced Collaboration through a Common Data Environment (CDE)

Centralized CDE platforms like BIM 360 or ACC enables the real-time collaboration among the multidisciplinary teams. Version control, access management and design tracking ensures that everyone works on the latest model version, reducing the communication gaps.

5) 4D and 5D Integration for Efficient Execution

Integrating 4D (time) and 5D (cost) data into the MEP BIM models enhances construction sequencing and cost estimation. Studies shows that projects using BIM for MEP coordination achieve up to 20% faster construction timelines and 10–15% cost savings.

Future-Ready MEP Modeling with BIM Services

The adoption of BIM for MEP design is rapidly transforming how the engineers and contractors collaborate. With increasing emphasis on sustainability, energy modeling and smart building integration, MEP BIM Services are evolving beyond the coordination tools—they now drive the predictive maintenance, digital twin development and lifecycle management.

According to the Dodge Data & Analytics (2024), over 73% of contractors report improved project efficiency and reduced change orders after implementing BIM-based MEP coordination. This underscores that MEP BIM is not just about better drawings—it’s about the better project delivery.

Conclusion

BIM Modeling for Complex MEP Systems streamlines the multidisciplinary coordination, enhances the design accuracy and reduces the construction risks. While challenges like space constraints and data management persist, the right BIM Services and workflows can transform the complexity into clarity.

As MEP systems continues to evolve with smart technologies and sustainability demands, adopting the advanced MEP BIM Services is no longer optional—it is a must for staying competitive in the modern AEC ecosystem.